News

SFH Successfully held 2 Million Kilometers No Major Repair Engine Dismantling Event

2024-01-30

2024-01-30

On January 12, 2024, SFH 2 million kilometer non major repair engine disassembly event with the theme of "Verification of extraordinary over a Million" was successfully held at SFH factory in Chongqing. The industrial media together with fellow truck drivers, verified the professional disassembly process of the SFH engines.

The Dismantled engine is a SFH CURSOR9 engine equipped on SAIC Hongyan vehicles, which has been responsible for the transportation of iron and steel since it was purchased by Yunnan Desheng Logistics in 2009. The complex and ever-changing road conditions and high-intensity working environment in Yunnan area challenges to the performance and durability of vehicles and engines. However, during its 13 year high load operation, this engine has undergone countless cycles of hot and cold alternations and load changes, maintaining a stable performance and efficient operation, setting an astonishing record of 2 million kilometers without major repairs. Subsequent ECU data reading revealed that this engine had a running time of 34867 hours and an actual mileage of 2335593 kilometers, far exceeding 2 million kilometers.

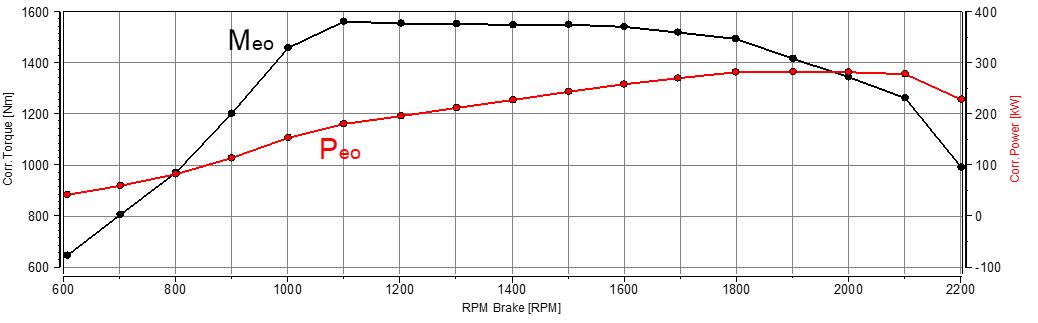

Before disassembly, SFH conducted the performance tests on the engine. The designed maximum power of the C9 GBIII is 280kw/2100rpm, and the maximum torque is 1500Nm/1100-1500rpm. From the external characteristic curve tested in the figure below, it can be seen that the maximum power is achieved at four points: 1800rpm, 1900rpm, 2000rpm, and 2100rpm. In the torque curve, the torque in the speed range of 1100rpm to 1700rpm is above 1500Nm, with the maximum torque reaching 1553Nm. From the data, it can be seen that the performance of this engine is far exceeds our expectations, after running for over 2 million kilometers.

During the dismantling process, SFH technician provided a detailed introduction to the design and manufacturing details of this engine. Intended to analyze the reason of no major repairs for 200W kilometers through engine usage. The dimension inspection of key components after disassembly, such as crankshaft journal, connecting rod journal, crankshaft bearing, connecting rod bearing, thrust plate thickness, piston ring thickness, camshaft journal, etc., mainly remains within the designed tolerance range, which fully proves the advanced manufacturing process and reliability of SFH engine.

According to the user's introduction, this engine has been regularly maintained for 13 years, using original parts and never using inferior parts, which is also the reason of why the engine maintains good condition. During the live broadcast event, SFH technician also emphasized the importance of original parts, introduced the difference of SFH original and non-original filters, and emphasized the methods of identifying genuine products. SFH firmly upholds the legitimate rights and interests of its clients, providing them with original parts with quality assurance, thereby extending the engine’s service life and maintaining its good operating condition.

Since the stability and durability of engines are crucial for customer operational efficiency and cost control, SFH always adhere to the pursuit of excellence in the design and production process, ensuring that every engine delivered to customers can meet or even exceed their expectations. This CURSOR 9 engine has no major repair records since delivery, which not only improves the operational efficiency of the fleet, but also saves maintenance costs for the fleet and brings excellent user experience.

At the same time, this CURSOR engine with no major repair record of 2 million kilometers is just a microcosm of many outstanding SFH products. On a global scale, there are lots of SFH engines running stably and efficiently on various vehicle equipment, creating huge value for customers. SFH CURSOR engine dismantled in this event, is not only the highest praise for the durability and reliability of SFH engines, but also a recognition of SFH's long-term commitment to product quality and customer value.

This milestone achievement not only marks a significant milestone in the journey of SFH, but also sets a new benchmark in the field of engines. In the future, SFH will continue to uphold the core values of "customer-centric" and continuously provide more high-performance and durable engine products to meet the growing power needs of customers.